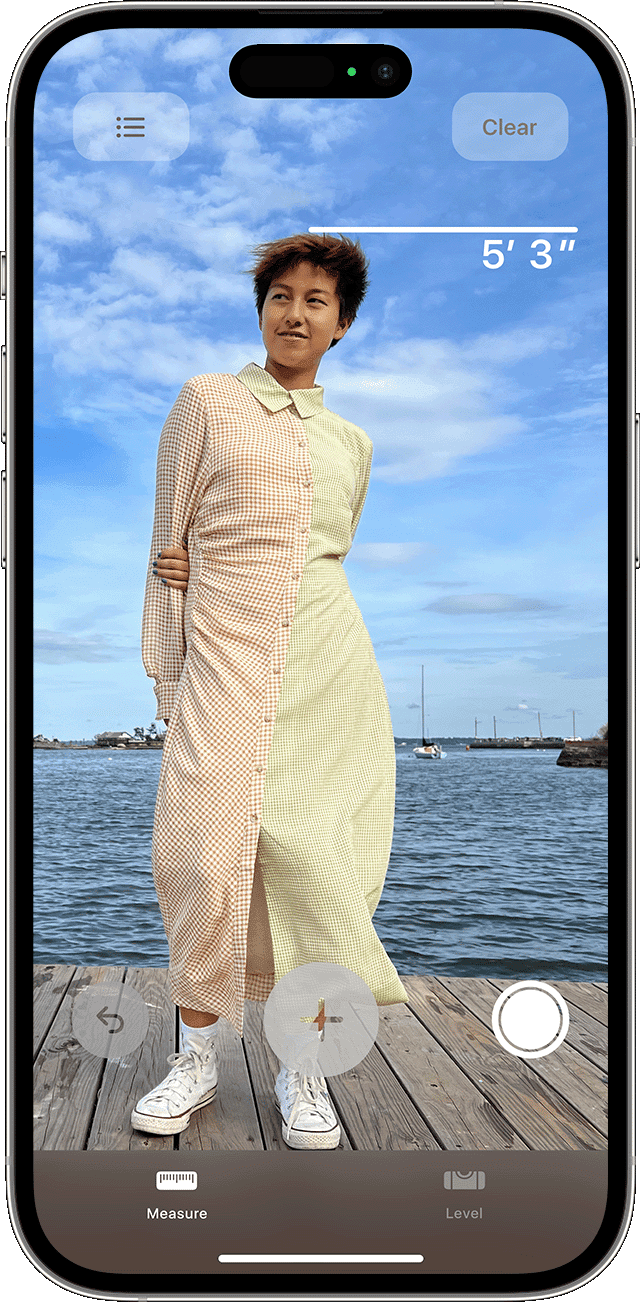

Does Facebook Notify When You Save A Photo?

Many Facebook users are concerned about their privacy when sharing photos on the platform. They often wonder…

Many Facebook users are concerned about their privacy when sharing photos on the platform. They often wonder…

If you’re trying to reach Temu’s customer service via phone, make sure to call (888) 495-8368. For…

Yes, you can measure your height with a cell phone, but it depends on your phone model….

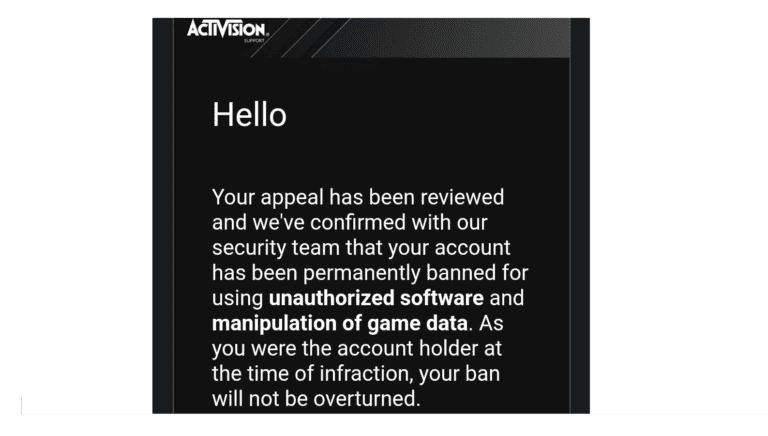

Sometimes Activision bans players’ accounts. You can appeal these bans. Bans are usually triggered by violating the…

Fans of the post-apocalyptic video game series have a new reason to mark their calendars for 2024….

When it comes to powering devices, the longevity of battery brands is a crucial consideration. A battery’s…

Moving TikTok drafts to a new phone can seem challenging. Users often spend considerable time creating content…

With the rising importance of social media in today’s communication landscape, Twitter is a critical platform for…

Adjusting the fan speed of a GPU, or graphics processing unit, is an essential aspect of managing…

Facebook Marketplace is a great place to find used goods, local services, and even new items. You…

Choosing the right case for your iPhone 15 is crucial. You want protection and style without breaking…

Palworld offers a unique feature that can significantly enhance your gaming experience: console commands. These commands, often…

If you’ve noticed that your AirTag is beeping, it likely indicates that something requires your attention. The…

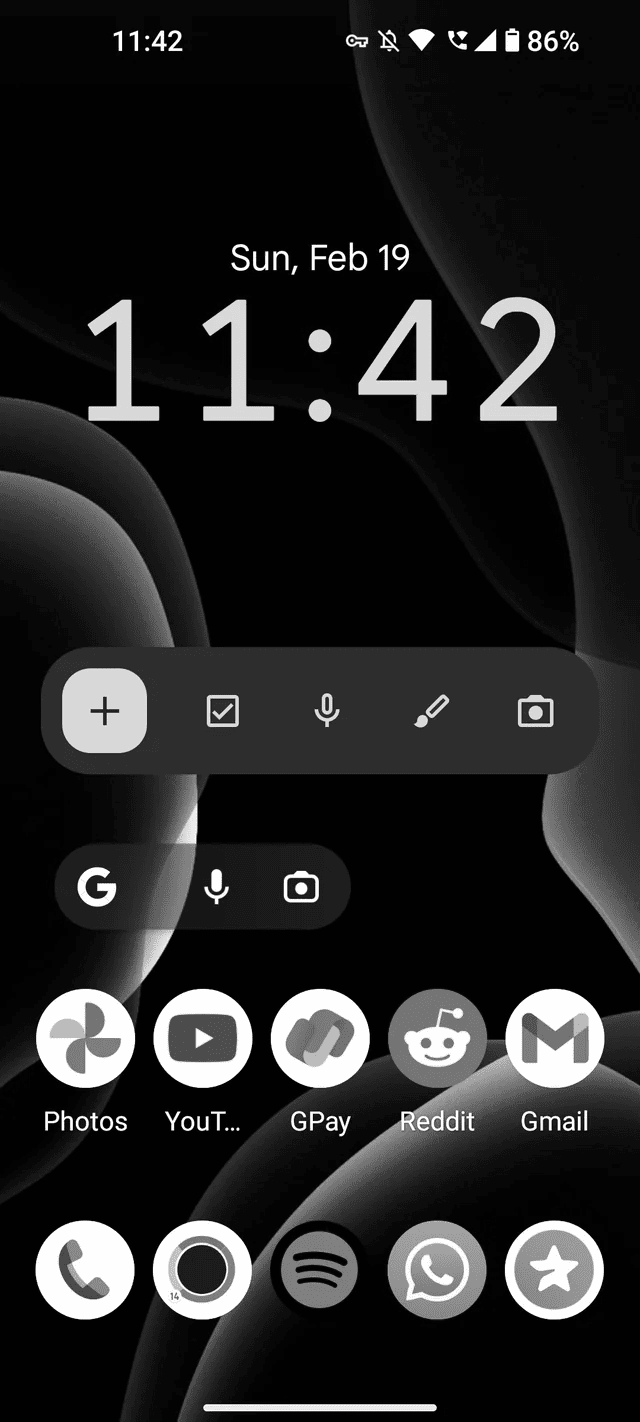

Encountering a phone screen that suddenly loses color, turning grayscale, can be unexpected and confusing. This often…

Weather apps have become indispensable tools in our daily lives, providing us with immediate and accurate weather…

With the vast user base of Facebook, getting constant notifications like ‘People You May Know’ can become…

Computer hardware issues can arise from various faults or failures within a system’s components. Common problems include…

Apple’s AirTag helps users keep track of their personal items through the Find My app on an…

Turning on a desktop PC typically involves pressing its power button. However, situations may arise where the…

Experiencing lag on your PS5 can disrupt your gameplay and diminish your enjoyment. When you encounter performance…

Cancelling an EOS Fitness membership requires specific steps to ensure the process is completed correctly. Members seeking…